In the world of heavy fabrication, the importance of safety and efficiency cannot be overstated. Whether you are working with heavy-duty metalwork, machinery, or large-scale construction projects, ensuring that these tasks are carried out efficiently and safely is paramount. One tool that plays an essential role in this process is the overhead crane. Overhead crane services are a critical component in heavy fabrication projects, as they help streamline operations and reduce risks. In this blog, we will explore three ways that overhead crane service enhances both safety and efficiency in heavy fabrication, specifically in areas like Atmore and similar locations where these projects are common.

Enhancing Worker Safety with Precision Lifting

One of the most significant advantages of overhead crane service in heavy fabrication is its ability to improve worker safety. When dealing with heavy-duty metalwork, lifting and moving materials can become a hazardous endeavor. Traditional methods such as forklifts or manual handling of materials often introduce a significant amount of risk, both to workers and the materials being handled.

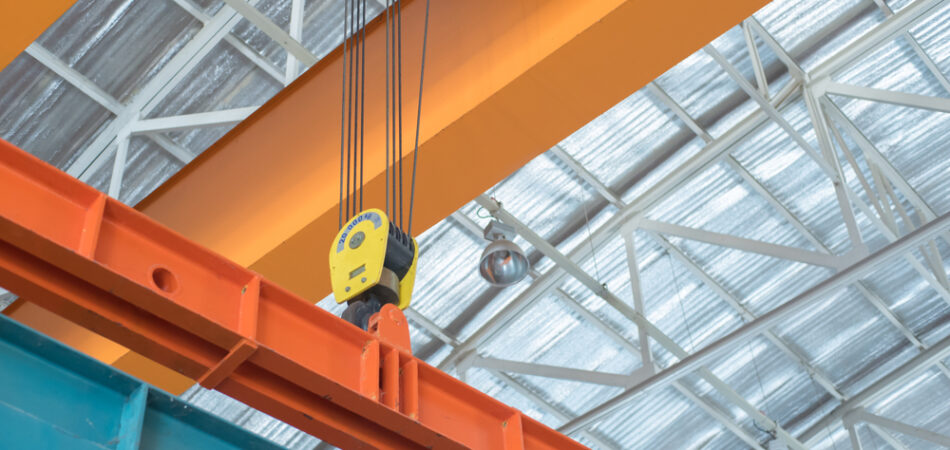

Overhead cranes, however, allow for precise, controlled movements of materials, minimizing the risk of accidents and injuries. The key to this enhanced safety lies in the crane’s ability to lift heavy loads smoothly and steadily. These cranes are designed to move loads with precision, allowing operators to place materials exactly where they are needed, whether it’s a large metal beam, machinery part, or other heavy materials. By eliminating the need for manual labor in lifting these items, overhead crane services drastically reduce the potential for workers to sustain injuries like strains, sprains, or worse, crush injuries.

In a busy fabrication environment, such as a workshop in Atmore or similar locations, the ability to lift and move materials without human error is invaluable. Overhead cranes can be operated remotely or with advanced controls, allowing workers to avoid being in close proximity to hazardous loads. This separation between the worker and the load not only increases safety but also provides peace of mind to everyone on the job site.

Boosting Efficiency Through Streamlined Operations

When working on a heavy fabrication project, efficiency is crucial to meet deadlines and reduce costs. Overhead cranes play an essential role in improving workflow and productivity by allowing materials to be moved quickly and efficiently across the workspace. In a typical fabrication shop, materials need to be transported from one section of the facility to another, such as from the cutting station to the welding station. With an overhead crane, these movements can be made swiftly and with minimal downtime.

The ease with which these cranes can be adjusted for different tasks also contributes to efficiency. Overhead cranes come equipped with versatile features that allow them to be adjusted for various lifting capacities and movement types. This adaptability ensures that materials of all shapes and sizes can be lifted, transported, and positioned with minimal hassle. Additionally, some cranes can be equipped with different lifting devices such as magnets or slings, allowing for a broader range of materials, from flat plates to cylindrical pipes, to be handled effortlessly.

In heavy fabrication projects, every minute counts, and the ability to move materials quickly and efficiently can make the difference between meeting project timelines or falling behind. With overhead crane service, projects in places like Atmore benefit from quicker turnaround times and reduced idle time for workers. The streamlined process enabled by cranes helps increase overall production capacity and improve project completion rates, providing a clear advantage to businesses in the competitive world of heavy fabrication.

Minimizing Material Damage with Gentle Handling

Material damage is an unavoidable risk in any fabrication environment. Mishandling or rough transportation of heavy-duty metalwork can lead to expensive material damage, waste, and delays. Overhead cranes, however, are engineered to prevent such issues. These cranes feature lifting mechanisms that ensure materials are handled gently and with the utmost care.

The primary benefit of an overhead crane in terms of material handling is the smooth and even lifting motion it provides. Unlike forklifts or other ground-based lifting equipment, which can sometimes cause jarring movements that may lead to scratches, dents, or other damage to the material, overhead cranes offer a more controlled, gentle lift. This is particularly important in the context of heavy-duty metalwork, where even a small scratch or dent can compromise the integrity of the material or increase costs associated with repairs or rework.

Furthermore, the advanced technology used in overhead crane services often includes sensors and controls that monitor the weight and position of the load. This precision ensures that materials are lifted and placed correctly, preventing any potential damage from overloading or improper handling. For heavy fabrication companies in Atmore and similar areas, this added level of care ensures that high-value materials are preserved, ultimately contributing to lower material costs and fewer delays caused by damaged goods.

Reducing Labor Costs and Improving Productivity

Labor costs in heavy fabrication can be significant, particularly when many workers are needed to handle, move, and position materials. The introduction of overhead crane services can dramatically reduce the number of workers required for material handling, allowing businesses to allocate their labor resources more efficiently. With cranes in place, one trained operator can manage the movement of several heavy materials at once, eliminating the need for multiple workers to perform the same tasks.

This reduction in the number of workers needed for material handling does not only cut down on direct labor costs but also allows workers to focus on higher-value tasks that contribute to the completion of the project. By minimizing time spent on transporting materials, overhead crane service allows the workforce to concentrate on activities such as fabrication, welding, and assembly, thus improving overall productivity and output. In fabrication environments in Atmore and other regions, these time savings translate into better profitability and faster project completion times.

Additionally, fewer workers are exposed to the physical strain and hazards associated with manual lifting, which means a lower likelihood of injury and a decrease in related costs such as medical expenses, insurance claims, and lost work hours. This aspect of crane service not only helps in cost reduction but also promotes long-term workforce health and job satisfaction, creating a safer and more efficient working environment overall.

Increasing Operational Flexibility and Versatility

In heavy fabrication, the work environment is dynamic, with varying tasks and unpredictable demands. Overhead cranes offer significant flexibility and versatility in such settings, as they can be used for a wide range of lifting and moving tasks. Whether lifting large steel plates, moving heavy machinery parts, or transporting equipment from one section of the facility to another, overhead cranes can be adapted to fit nearly any need.

The versatility of overhead cranes also extends to their ability to integrate with other equipment and systems. For example, cranes can be combined with automated conveyors or robotic systems to create an even more efficient workflow. Additionally, modern overhead crane systems come equipped with smart technology that allows for predictive maintenance, ensuring that cranes are always in optimal working condition. This operational flexibility makes overhead crane services indispensable in complex and fast-paced fabrication environments where the ability to adapt quickly can make a significant difference in overall performance.

In places like Atmore, where heavy fabrication projects are often diverse and large in scale, overhead cranes provide the adaptability required to handle a wide variety of materials and tasks. This flexibility enables businesses to take on different types of projects without having to invest in additional specialized equipment for each unique job, making overhead crane service a cost-effective and scalable solution.

Conclusion

Overhead crane services are indispensable for enhancing both safety and efficiency in heavy fabrication projects. By improving worker safety through precise lifting, boosting efficiency by streamlining operations, minimizing material damage, reducing labor costs, and increasing operational flexibility, overhead cranes provide a comprehensive solution for businesses involved in heavy-duty metalwork and fabrication. For companies in regions like Atmore, these benefits contribute to smoother operations, faster project completion, and a safer, more productive workforce. Whether for large-scale construction projects or day-to-day fabrication, overhead cranes are a vital asset that can make a significant impact on any heavy fabrication operation.

Need a Machine Shop in Atmore, AL?

Escofab Inc. has been dedicated to providing quality machining and fabrication since 1981! Here at Escofab Inc. we utilize fabricating and machining to your specifications. We work to fit your needs and ensure customer satisfaction. Our friendly and informative staff are eager to assist you! Give us a call or come on in today; walk-ins welcome!