Choosing the right metal fabrication partner is one of the most crucial steps you’ll take in the lifecycle of any custom industrial or commercial project. From design to delivery, the capabilities and reliability of your fabrication partner can have a significant impact on cost, lead time, product quality, and ultimately, customer satisfaction. Whether you’re building prototypes, large-scale machinery, or intricate architectural components, a trusted partner in custom fabrication services can be the difference between seamless success and costly setbacks.

To navigate this critical decision, it’s essential to ask the right questions up front—questions that go beyond the basics of capabilities and pricing. This guide explores five essential questions to help you evaluate potential partners and make an informed decision before your next project begins.

What Is Their Experience With Your Industry and Product Type?

Not all metal fabricators are created equal. Some specialize in construction components, while others focus on precision electronics, aerospace parts, or consumer products. Experience matters greatly in metal fabrication because the materials, processes, tolerances, and compliance requirements vary widely across industries.

When evaluating a metal fabrication partner, ask about their track record with projects similar to yours. A fabrication company that routinely works with architectural steel, for example, may not be the best fit for high-precision medical device components. If they have industry-specific certifications (like ISO 9001, AWS, or ASME), even better—these indicate a deeper level of quality control and operational maturity.

You should also request samples or case studies that demonstrate past work relevant to your needs. Look for evidence of quality, consistency, and complexity in their completed projects. It’s one thing to say they’ve worked on a specific type of part, but it’s far more telling to see how well those parts were executed, whether they were delivered on time, and how the partnership was managed.

Do They Offer End-to-End Custom Fabrication Services?

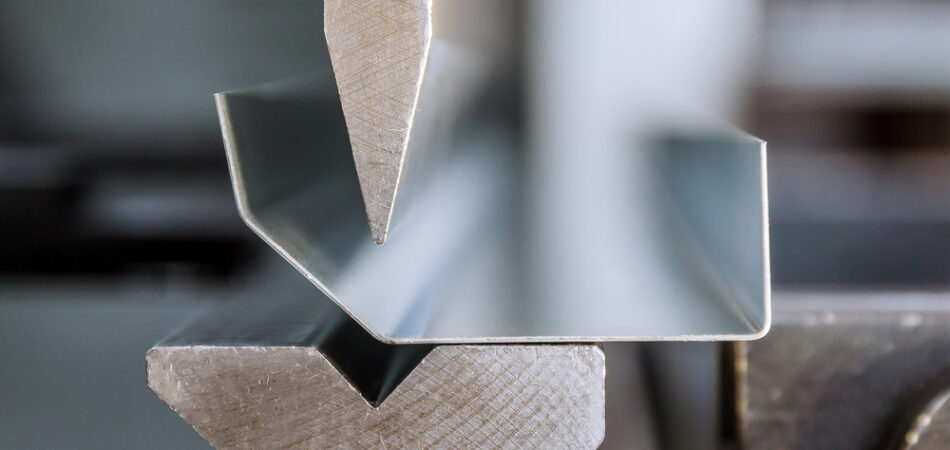

Custom fabrication isn’t just about cutting and welding metal—it’s a multi-step process that includes design engineering, material sourcing, machining, forming, finishing, assembly, and sometimes even logistics. An ideal custom fabrication services provider should be able to guide you through this entire journey.

Ask if they have in-house capabilities for engineering support, 3D modeling, and rapid prototyping. These services are invaluable in the early stages of a project when minor changes can lead to major cost savings or performance improvements. Also inquire about their equipment and technologies—do they use CNC machines, fiber laser cutting, or automated robotic welding systems? Are their inspection and quality assurance procedures robust?

Even if you’re starting with a fully developed set of CAD files, it helps to work with a partner who can provide feedback on manufacturability, tolerances, and materials. This engineering collaboration can identify and eliminate problems before they impact production.

Lastly, consider whether the partner can scale with you. Do they offer small-run prototyping as well as high-volume production? If your project grows or pivots, can they adjust quickly and continue to meet your needs?

What Quality Control and Certifications Do They Have?

Precision and reliability are the cornerstones of great fabrication. A small defect in a machined component or weld can compromise an entire structure or system. That’s why it’s critical to choose a metal fabrication partner with rigorous quality control procedures and recognized certifications.

Before committing to a partner, ask to review their quality assurance policies. Do they perform inspections at each stage of production? Are they equipped with coordinate measuring machines (CMMs), laser scanners, or other tools for high-precision measurement? What’s their documented rejection rate or rework percentage?

Third-party certifications can also offer peace of mind. ISO 9001 certification indicates adherence to globally recognized quality standards, while industry-specific credentials (such as AWS D1.1 for structural welding or AS9100 for aerospace fabrication) demonstrate an even deeper level of commitment.

Also, inquire about their traceability protocols. Can they provide full documentation for materials used, such as mill test reports or certificates of compliance? In regulated industries like oil & gas or defense, traceability is not just a nice-to-have—it’s a legal requirement.

A professional fabrication partner won’t shy away from these questions. Instead, they’ll have transparent answers, documented policies, and the records to back them up.

How Transparent and Reliable Is Their Communication?

Even the most technically proficient fabricator can fall short if they lack strong communication skills. A project’s success often hinges on how well updates are shared, how quickly issues are resolved, and how clearly expectations are set on both sides.

When assessing a potential partner, pay attention to their responsiveness from the first point of contact. Do they reply to inquiries promptly and thoroughly? Are they proactive about asking clarifying questions and offering helpful suggestions? This early behavior is often a strong predictor of what the working relationship will be like once a project is underway.

You should also ask how project updates are handled. Will you have a dedicated point of contact? How often will progress reports be shared, and through what channels? Transparency in scheduling, pricing, and production timelines is essential to maintaining trust and minimizing surprises.

Consider their willingness to engage in problem-solving discussions, especially if design changes or supply chain disruptions occur. A truly dependable custom fabrication services provider will view communication as a collaborative process—not just a formality. They should also be willing to visit your site (or host you at theirs) if needed, and offer clear documentation for each phase of the project.

Can They Meet Your Budget and Timeline—Without Compromising Quality?

Cost and turnaround time are two of the most pressing concerns in any fabrication project. But a low quote or quick delivery promise should never come at the expense of quality or reliability. That’s why it’s essential to have a clear conversation with your potential metal fabrication partner about how they balance these factors.

Request a detailed estimate that breaks down labor, materials, tooling, and any ancillary costs. Transparency here is key—an itemized quote gives you a better understanding of how they operate and helps you avoid hidden fees later. If the pricing seems too good to be true, it probably is. Cutting corners to win a job can lead to poor workmanship, missed deadlines, and ultimately higher costs through rework or lost time.

Similarly, ask about their production schedule and whether they have the capacity to meet your timeline. If they’re overbooked or lack sufficient automation, delays are likely. On the other hand, if they have scalable systems and contingency plans in place, it’s a good sign they can deliver on time.

You should also evaluate how they handle rush jobs or unexpected changes. Are they flexible in the face of evolving project scopes? Can they ramp up production if demand increases? Their ability to stay agile while maintaining quality standards is an important marker of long-term viability.

Ultimately, your goal is to find a fabrication partner who can deliver a high-quality product within your required timeline and budget—but who is also candid about potential constraints and capable of problem-solving when challenges arise.

Conclusion

Choosing a metal fabrication partner isn’t just a procurement decision—it’s a strategic move that will affect the success of your entire project. By asking the five questions outlined in this guide, you can gain a comprehensive view of each potential partner’s capabilities, quality standards, communication practices, and overall reliability.

Whether you’re sourcing custom fabrication services for the first time or looking to upgrade from an existing provider, the right partner should feel like an extension of your team. They’ll be invested in your goals, responsive to your concerns, and uncompromising in their pursuit of quality. Take the time to vet them thoroughly—and you’ll reap the benefits in both performance and peace of mind.

In the end, the right questions lead to the right partnerships. And in fabrication, the right partnership is what turns blueprints into breakthroughs.

Need a Machine Shop in Atmore, AL?

Escofab Inc. has been dedicated to providing quality machining and fabrication since 1981! Here at Escofab Inc. we utilize fabricating and machining to your specifications. We work to fit your needs and ensure customer satisfaction. Our friendly and informative staff are eager to assist you! Give us a call or come on in today; walk-ins welcome!