Rapid prototyping has emerged as one of the most significant technological advances in product development, enabling companies to transform ideas into tangible products faster than ever before. At its core, rapid prototyping is the process of quickly creating a scaled or functional model of a product to test, refine, and validate concepts before moving into full-scale production.

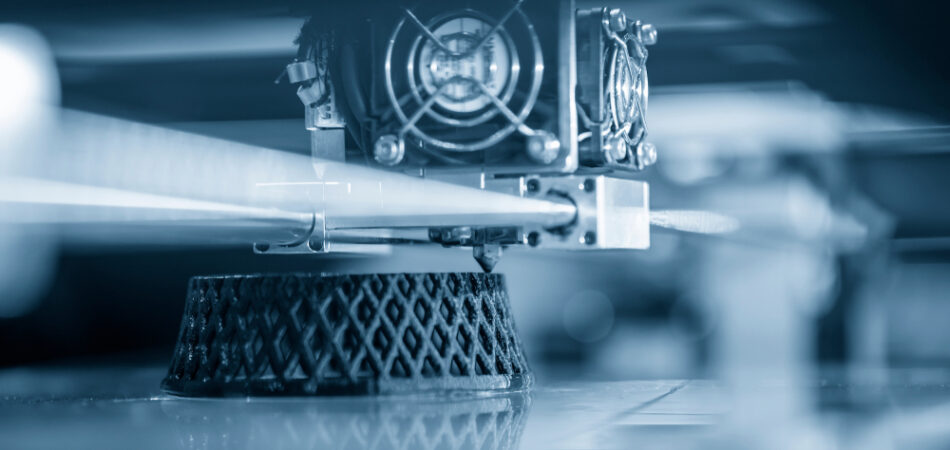

The method utilizes advanced tools such as 3D printing, CNC machining, and computer-aided design (CAD) software to produce prototypes within a short timeframe. Unlike traditional methods, which often require weeks or even months, rapid prototyping can deliver working models in days or even hours. This speed not only accelerates decision-making but also empowers designers and engineers to explore more creative possibilities without being constrained by long development cycles.

Moreover, the role of rapid prototyping in product development extends beyond just building physical models. It fosters collaboration between cross-functional teams, allowing engineers, designers, and stakeholders to visualize concepts, evaluate functionality, and make informed choices early in the development lifecycle. This reduces risks, lowers costs, and increases the chances of market success.

Accelerating the Product Development Lifecycle

Traditional product development processes often relied heavily on sequential stages where design, testing, and production occurred one after another. This rigid approach limited flexibility and made it costly to implement changes after initial designs were finalized. Rapid prototyping disrupts this pattern by introducing an iterative model where ideas can be tested and improved in near real time.

In the early stages of product development, teams can use rapid prototyping to create low-fidelity models that focus on form, structure, and usability. These prototypes act as an initial visualization of the concept and allow for immediate stakeholder feedback. Based on this input, refinements can be made quickly, ensuring that the final design aligns with both user expectations and technical feasibility.

Once the design matures, high-fidelity prototypes incorporating materials, textures, and functional components can be produced. These models closely resemble the final product and are invaluable for testing ergonomics, durability, and performance under realistic conditions. By uncovering potential flaws early, companies can avoid costly redesigns and production delays, ultimately bringing better products to market faster.

Rapid prototyping also aligns seamlessly with agile methodologies, where adaptability and continuous improvement are prioritized. Instead of waiting until the end of the development cycle to evaluate performance, teams can gather data at every stage, fine-tune their designs, and confidently move forward knowing that each iteration is backed by tested insights.

Enhancing Collaboration and Innovation

One of the most significant advantages of rapid prototyping in product development is its ability to foster collaboration across diverse teams. Product innovation often involves contributions from engineers, designers, marketers, and executives, each bringing a unique perspective to the table. However, miscommunication between these groups can lead to misunderstandings, delays, and rework. Rapid prototyping minimizes these challenges by providing a shared visual representation of the concept.

Having a physical or digital prototype available allows everyone involved to see, touch, and interact with the product. This tangible approach enhances understanding and promotes productive discussions. Stakeholders can provide specific, informed feedback rather than relying on abstract ideas or technical descriptions, resulting in better alignment between vision and execution.

Furthermore, rapid prototyping drives innovation by empowering teams to experiment without fear of failure. Since prototypes can be created quickly and affordably, designers are free to explore unconventional ideas and test multiple variations before committing to a single solution. This iterative exploration often leads to breakthrough designs that set products apart in competitive markets.

The collaborative environment created by rapid prototyping also strengthens relationships between businesses and their customers. By involving end-users early in the design process and integrating their feedback into prototypes, companies can create products that better meet customer needs, improving satisfaction and brand loyalty.

Reducing Risks and Costs in Product Development

Every stage of product development carries inherent risks, from design flaws and usability issues to market misalignment. The earlier these problems are identified, the easier and more cost-effective they are to fix. Rapid prototyping plays a critical role in risk mitigation by allowing teams to test assumptions and uncover potential issues long before production begins.

For example, if a product’s ergonomics are flawed, a prototype can reveal these shortcomings during the testing phase rather than after thousands of units have been manufactured. Similarly, functional prototypes can expose material weaknesses, compatibility issues, or performance limitations under different environmental conditions. By resolving these challenges upfront, companies avoid expensive recalls, redesigns, and production delays.

In addition to risk reduction, rapid prototyping significantly lowers development costs. Traditional manufacturing methods often require specialized tooling and molds, which can be costly and time-consuming to produce. With rapid prototyping technologies like 3D printing, teams can bypass these initial expenses and create prototypes directly from digital models. The savings achieved during these early stages can then be reinvested into refining the product, enhancing its features, or improving its market readiness.

Moreover, shorter development cycles made possible by rapid prototyping allow businesses to capitalize on emerging opportunities and bring products to market faster than competitors. In industries where timing is critical, this speed-to-market advantage can define success or failure.

The Future of Rapid Prototyping in Product Development

As technology continues to evolve, the role of rapid prototyping in product development will only grow stronger. Emerging innovations such as advanced materials, AI-powered design tools, and multi-material 3D printing are expanding what’s possible for modern prototypes. Products can now be simulated, tested, and optimized digitally before the first physical model is even created, reducing development time even further.

Artificial intelligence and machine learning are also transforming rapid prototyping by analyzing user behavior, predicting potential design flaws, and suggesting improvements based on data-driven insights. Combined with augmented and virtual reality, teams can visualize prototypes in immersive environments, enabling more effective evaluations of scale, usability, and aesthetics without producing multiple physical models.

Additionally, sustainability is becoming a critical focus in product development. Rapid prototyping technologies are adapting by using recyclable and eco-friendly materials, reducing waste during the design phase, and supporting circular manufacturing practices. These innovations not only make product development more efficient but also align businesses with growing consumer demand for environmentally responsible solutions.

Looking ahead, companies that embrace these advancements will gain a competitive edge by delivering better products in less time, with greater precision and lower costs. The integration of rapid prototyping into broader digital manufacturing ecosystems will create new possibilities for customization, innovation, and speed — reshaping how products are conceived, developed, and launched.

Conclusion

From concept to completion, rapid prototyping has transformed the way businesses approach product development. By accelerating timelines, enhancing collaboration, reducing risks, and enabling innovation, it has become an indispensable tool for modern industries. Companies leveraging these capabilities are better equipped to adapt to changing market demands, respond to customer feedback, and maintain a competitive advantage.

As technology continues to evolve, rapid prototyping will only become more sophisticated, offering even faster, smarter, and more sustainable solutions. Organizations that adopt these tools and integrate them into their development strategies will position themselves at the forefront of innovation. In a world where speed, efficiency, and creativity drive success, rapid prototyping is no longer a luxury — it is a necessity for turning visionary ideas into market-ready products.

Need a Machine Shop in Atmore, AL?

Escofab Inc. has been dedicated to providing quality machining and fabrication since 1981! Here at Escofab Inc. we utilize fabricating and machining to your specifications. We work to fit your needs and ensure customer satisfaction. Our friendly and informative staff are eager to assist you! Give us a call or come on in today; walk-ins welcome!