Operational efficiency is synonymous with profitability. Downtime—planned or unplanned—is a critical challenge that can paralyze production lines, delay project timelines, and severely impact revenue. Whether it’s in automotive manufacturing, aerospace, oil and gas, or power generation, the continuous performance of machinery is essential. One of the most effective strategies to combat downtime is precision machining. Far beyond just a manufacturing method, precision machining plays a pivotal role in maintaining, repairing, and optimizing industrial equipment. By integrating precision machining into industrial equipment repair protocols, businesses can minimize disruptions, ensure component accuracy, and extend equipment lifespan.

The Link Between Precision Machining and Operational Reliability

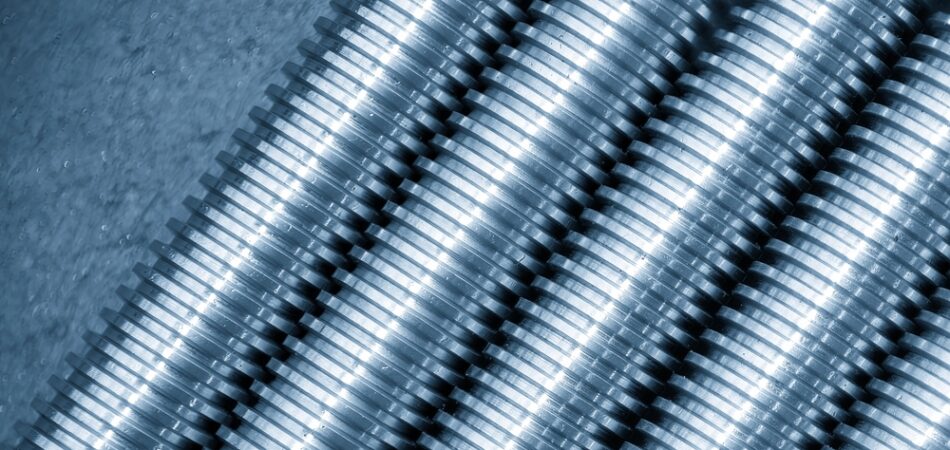

Precision machining involves the process of removing material from a workpiece while maintaining very tight tolerances. This high level of accuracy is critical in manufacturing complex parts that must fit and function exactly as intended. In the context of industrial equipment repair, precision machining is a cornerstone of restoring machines to their optimal operating conditions.

Downtime often stems from worn-out or broken components. When a part fails, replacing it quickly and accurately is the difference between hours and days of halted productivity. Standard replacement parts may not always be readily available, especially for legacy systems or custom machinery. In such cases, precision machining can reproduce exact replicas of failed components to original specifications—or improve upon them with better materials or refined tolerances. This ensures the repaired equipment performs as well—or even better—than before.

Furthermore, reliability isn’t just about individual parts. It’s about how every piece fits into the larger system. Misalignments, even by fractions of a millimeter, can lead to excessive wear, vibration, and premature failure. Precision machining ensures compatibility across all mating parts, thereby preventing cascading failures and reducing the frequency of breakdowns.

Minimizing Downtime Through Custom Component Fabrication

One of the standout benefits of precision machining in industrial equipment repair is the ability to fabricate custom components on-demand. For many operations, especially those involving specialized or outdated machinery, OEM parts may no longer be manufactured or may have prohibitive lead times. Precision machining offers a viable alternative—rapidly producing components that are tailored to the equipment’s exact requirements.

In emergency repair scenarios, having access to an in-house or local precision machining shop drastically reduces response time. Technicians can reverse-engineer broken parts, digitize them using CAD technology, and reproduce them using CNC machinery—all in a matter of hours rather than weeks. This rapid turnaround is critical for industries where every hour of downtime translates to thousands of dollars in lost production.

Moreover, precision machining enables upgrades during repair. Instead of merely replacing components, parts can be redesigned with improved geometry or more durable materials. For instance, a shaft that frequently fails due to bending can be remade with a stronger alloy and heat-treated for enhanced performance. Such proactive modifications enhance long-term reliability and reduce future downtime.

Extending Equipment Lifespan and Reducing Maintenance Frequency

Precision machining doesn’t just resolve current issues; it lays the foundation for longevity. Industrial machinery operates under immense stress. Components degrade over time due to friction, heat, vibration, and corrosive environments. Routine maintenance is essential, but its effectiveness is largely determined by the quality of the replacement parts and the precision of their installation.

When precision-machined parts replace worn components, they not only fit better but also function more efficiently. Less friction, reduced stress concentrations, and tighter tolerances mean the equipment operates more smoothly. This results in lower energy consumption, less wear on adjacent parts, and reduced maintenance frequency. Over time, this proactive approach translates into a longer equipment lifespan and fewer interruptions for service.

Additionally, precision machining supports condition-based maintenance strategies. Rather than relying solely on periodic overhauls, companies can monitor equipment performance and only intervene when necessary. When intervention is required, precision machining ensures the quality of repairs meets or exceeds the original build standards, maintaining the integrity of the machinery.

Case Studies: Real-World Impact of Precision Machining on Downtime

Across multiple industries, the integration of precision machining into industrial equipment repair has shown remarkable results. In the mining sector, for example, heavy-duty drills and crushers often experience extreme wear and tear. One mining operation in South America reported a 40% reduction in unplanned downtime after partnering with a local machine shop specializing in precision repair. Custom-machined bearings and bushings replaced factory parts that frequently failed, resulting in increased reliability and less need for emergency interventions.

Similarly, a power generation facility in the Midwest implemented a precision machining protocol for their turbine maintenance cycles. Previously, turbine blade replacements required ordering from overseas suppliers with lead times of up to three months. By investing in a local precision machining team, the facility reduced this lead time to under two weeks. Not only did this keep their turbines running, but it also gave them the flexibility to refine blade designs for better aerodynamics and fuel efficiency.

In another case, an aerospace components manufacturer leveraged precision machining to overhaul their assembly line robotics. Precision-ground gear sets and actuators replaced worn units, which previously caused sporadic shutdowns. The result was a 25% improvement in uptime and more consistent production output.

These case studies highlight a clear pattern: precision machining significantly enhances the effectiveness of industrial equipment repair, directly reducing downtime and boosting operational continuity.

Embracing the Future of Equipment Reliability Through Precision Machining

As manufacturing and industrial sectors continue to evolve, the demand for high-performance, reliable machinery grows. Emerging technologies such as AI-driven predictive maintenance, IoT sensors, and digital twins are reshaping the way equipment health is monitored. However, even the most advanced diagnostic tools are only as effective as the repairs that follow. That’s where precision machining remains irreplaceable.

Future-forward operations are already integrating precision machining into their digital maintenance ecosystems. For example, 3D scanning and CAD modeling allow technicians to virtually assess component degradation and preemptively machine replacements before a failure occurs. CNC machines, guided by this digital input, produce components with sub-micron accuracy, ensuring consistent quality and reducing variability.

Furthermore, additive manufacturing—often seen as a complement to precision machining—is being used to create near-net shapes, which are then finished using precision machining for critical tolerances. This hybrid approach speeds up production while maintaining the accuracy required for industrial equipment repair.

In essence, precision machining is not just about making parts; it’s about ensuring performance, reliability, and uptime in an increasingly demanding industrial environment. Companies that invest in precision machining capabilities—either in-house or through strategic partnerships—gain a competitive edge by minimizing downtime, protecting their assets, and ensuring smooth, uninterrupted operations.

Conclusion

Reducing downtime is not a luxury—it’s a necessity. And precision machining stands at the forefront of this effort. From immediate component reproduction to long-term performance enhancement, it offers a comprehensive solution to one of industry’s greatest challenges. As industrial equipment continues to grow more complex and expectations for uptime rise, precision machining will remain an indispensable tool in the maintenance and repair arsenal.

Need a Machine Shop in Atmore, AL?

Escofab Inc. has been dedicated to providing quality machining and fabrication since 1981! Here at Escofab Inc. we utilize fabricating and machining to your specifications. We work to fit your needs and ensure customer satisfaction. Our friendly and informative staff are eager to assist you! Give us a call or come on in today; walk-ins welcome!